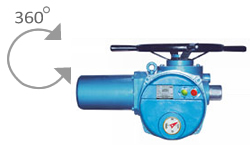

Multi Turn

Electric Actuators

Torque Range : 100 ~ 900 NM"Cair" offers Multi Turn Electrical Actuators used for Gate Valve.

ATM Series Electric Valve Actuator

ATM series electronic valve actuators are types of multi-turn valve electric actuators, which are manufactured by introducing the Limitorque technology from the US. They are the main body of the Limitorque electric actuators. ATM series products include nine specifications such as ATM-01, 03, 00, 1, 2, 3, 4, 5, which the ranges of output torque are 110-2700 N.m. Parts of the operator of ATM series products can combine with BA bevel gear or spur gear reducers, so that they become ATM/BA combined multi-turn electronic actuators. When they are combined with HBC worm gear reducers or with JA planetary reduction gears, they become combined quarter-turn electronic actuators. Limitorque valve electric actuators rank as top grade products and the following are the distinctive features.

The Stroke Control Unitis Feature of ATM Series:

The counter gear of the stroke control unit of ATM series is installed in the compassion-molded aluminum framework and under its cover, so the counter gear can be well lubricated when it is under the condition of accelerating drive.

Micro switch is not applied to the electric actuating device of the stroke control unit. Its torque control and stroke control device adopt self-cleaned wide contact rotary switch, which is made from copper-silver mixed material, thus it effectively improved the re liability of electric control, as a result the product is at the leading level in the country.

Another Feature of the stroke control unit of ATM series is that it can provide multi-contact. The form of the switch contact can ne arranged according to need, as well as can be set at normal open or normal close state at will.

The Torque Control Units Feature of ATM Series:

As it adopted intermeshing between the annular rack of the gear pedestal and the torque switch shaft gear, the conflict problem between the torque signals, which most actuators have, can be averted. To some extent, it improved the reliability of torque control.

Tailor-made deep groove ball bearing and check ring used in the hole is employed so that it can bear the axial thrust force fromthe worm stem in two ways. Otherwise its dimension is smaller.

The disk springs are forged by adopting oscillating rolling technology, the components are long-life and more reliable. The limit sheath set outside the springs can protect them from ductile deformation.

For ATM-04, 03, 3, 4, light, medium or heavy disk springs can be chosen according to different output torque; for ATM-00-2, two kinds of disk springs can be chosen, i.e. one set of light and one heavy springs can be used together, this combination can effectively enlarge the adjustable range of the torque and make the adjustment to the minimum control torque more convenient

Application

Widely used in the fields such as petroleum, Chemical Industry, Power plant. Metallurgy, Pharmacy, Paper Industry Energy, Water treatment vessel. Textile, Food processing Building, Automation, Thermic Fluid lines for furnace & Steam boilers.

The Driving Sleeve's Feature of ATM Series:

The driving sleeve of ATM series has its distinctive feature, i.e. the valve stem nut is input. Due to the nut is emplaced on theelectric actuator so that it simplified the construction of flange section of the valve and reduced customers cost.

While the electric valve is on service, it is convenient to lubricate the nut and the threaded spindle and to change or maintain the nut.

The nut is located in the driving sleeve so that it is easy for axial floating locating it by employing the disk spring sheath so ttiat the structure of high temperature and high speed version can come true.

The MDPI Units Feature SMC Series

Less in volume, easy for mounting, transmitting with equilibrium, low failure rate.

With wide range of transmission ratio, it can satisfy stroke control for values of various diameters.

Clear in indication on site, convenient for adjustment.

Various types of components for value position contact sign feedback, satisfying different control needed.

ATM series products can be controlled singly or collectively; and can be controlled on site or in a control room from distance.

| Products title | Series code-name | Products types | Variety | ||

| Electro-motion valve equipment | ATM ATM/HBC | Multi-turning Part-turning | General type | Self-regulating type | Basic type |

| Basic type | Diploid speed type (level of nuclear) | Button on lamp-box type | |||

| Resist radiation type (level of nuclear) | Remote control type | Whole | |||

| SCO | Multi-turning | High temperature and high speed type (particular technique type) | |||

| Hand valve equipment | BA | Multi-turning | General type | Basic type | |

| MSG/HBC VGC | Part-turning | Opening Limit show type | |||

| Switch signal type | |||||

ATM Series Electronics Multy-True Valve Actuator

Applicable valve: gate valve, stop valve.

Range of control torque: 100 ~ 27,OOON.M.

Output speed: 6 ~ 100r/min.

Open protect grade: IP65-IP67-IP68.

Ambient temperature: -20 ~ 55°C (Temperature outside the above range, please statewhen ordering)

Version provided: Basic version, with push-button version, integral version, with VOT version (Capable of output electric signal of 4 ~ 20), auto-regulation version (Capable of input and output electric signal of 4 ~ 20), two-speed version, remote control version, general-wire version, etc

Choice stroke control contact amount:

4R-2C=8 double contacts 4R-4C=16 double contacts

2R-2C=4 double contacts 2R-4C=8 double contacts

(The contact state based on the standard or customer requirements)

Choice torque control contact amount: Basic version provides a pair of large contacts respectively on open and close position.(If normal open, normal close contacts are needed, please state when ordering).

Special versions derived: Explosion-proof version (Explosion-proof grade: Exd II BT4, if the more advanced is needed, please state when ordering), high temperature and high-speed version, submerge I & II version. Low temperature I & II version, ship-used version, fireproofing version, anti-radioactive version (nuclear grade), and so on.

ATM Series Electronics Multy-True Valve Actuator (Special Version Derived)

ATM series integral explosion-proof version electronic multy-turn valve actuators Explosion-proof grade: ExdIIBT4.

SCO series high-temperature and high-speed version electronic multy-turn valve actuators The temperature of media: 480°C.

Electronic valve actuator of nuclear grade Ex-safety-island Electronic valve actuator of IE grade.

Electronic valve actuator of sail usage grade.

The Stroke Control Unit Feature

The stroke control device adopts self-cleaned rotary large con¬tact switch, which is made from copper-silver mixed material, it has high reliability in controlling and with a large amount control contacts, the contact state can be set arbitrarily, which are its main features. It can satisfy various control types.

Torque Control Unit Feature

There are two type of switch that is self-purification big contact switch closed at every turn and high capability switch with fine motion. It has characteristics of high reliability control, well ap¬plicability and so on. It is accurate and reliable to output stan¬dard of inertia of auto electric equipment.

The Location Indication Frameworks Feature

It adopts many double of gear group with small modulus fittings, which can indicate accurate location and show 100% scale of finger valve location on site used for any caliber, and can com¬plete electric signal is feedback using common electric position instrument or accurate one.

Industries Served

| Power plant |

| Steel plant |

| Municipal Drainage systems |

| Water Supply Board |